Laser Drilling Equipment Processing Technology Selection

2019-08-12source:access:3085

I. Characteristics of laser drilling

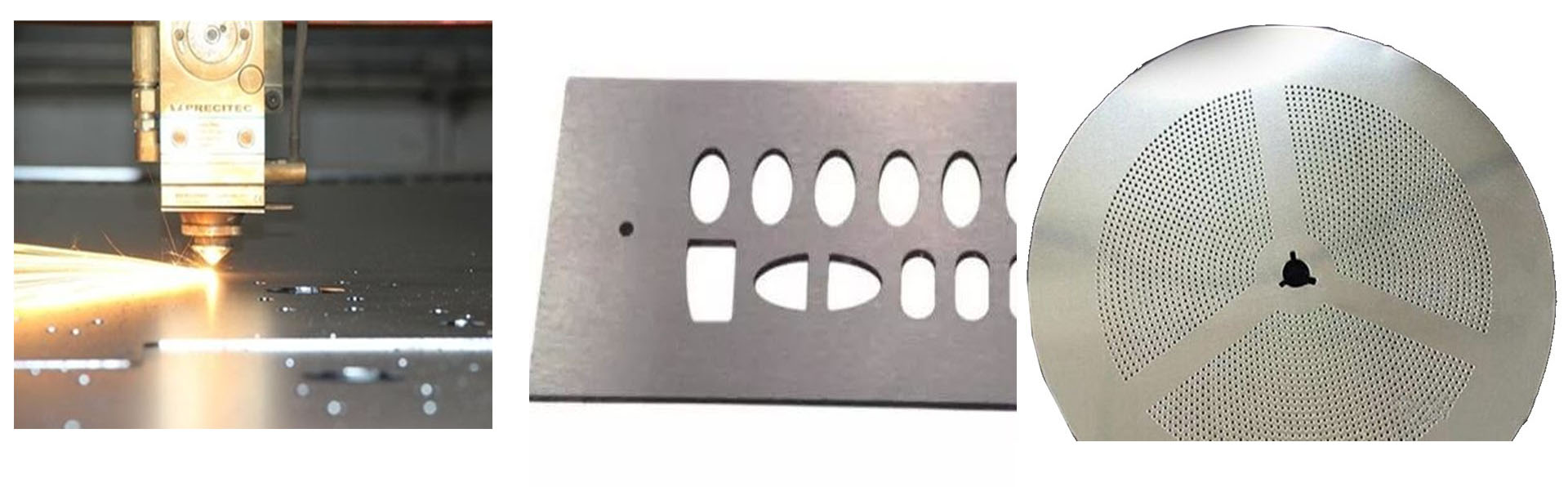

Laser drilling is the first practical laser processing technology and one of the main application areas of laser processing. With the rapid development of modern industry and science and technology, more and more materials with high hardness and high melting point are used, and the traditional processing methods can not meet certain process requirements. For example, processing micron-sized pores on high-melting-point metal molybdenum sheets, processing small holes of several tens of micrometers on hard tungsten carbide, processing deep holes of several tens of micrometers on red and sapphire, and jetting of diamond wire drawing dies and chemical fibers Silk head and so on.

This type of machining task is difficult and sometimes impossible with conventional machining methods, and laser drilling is not difficult to achieve. The high concentration of the laser beam in space and time can reduce the spot diameter to the micron level to achieve high power density, and laser drilling can be performed on almost any material.

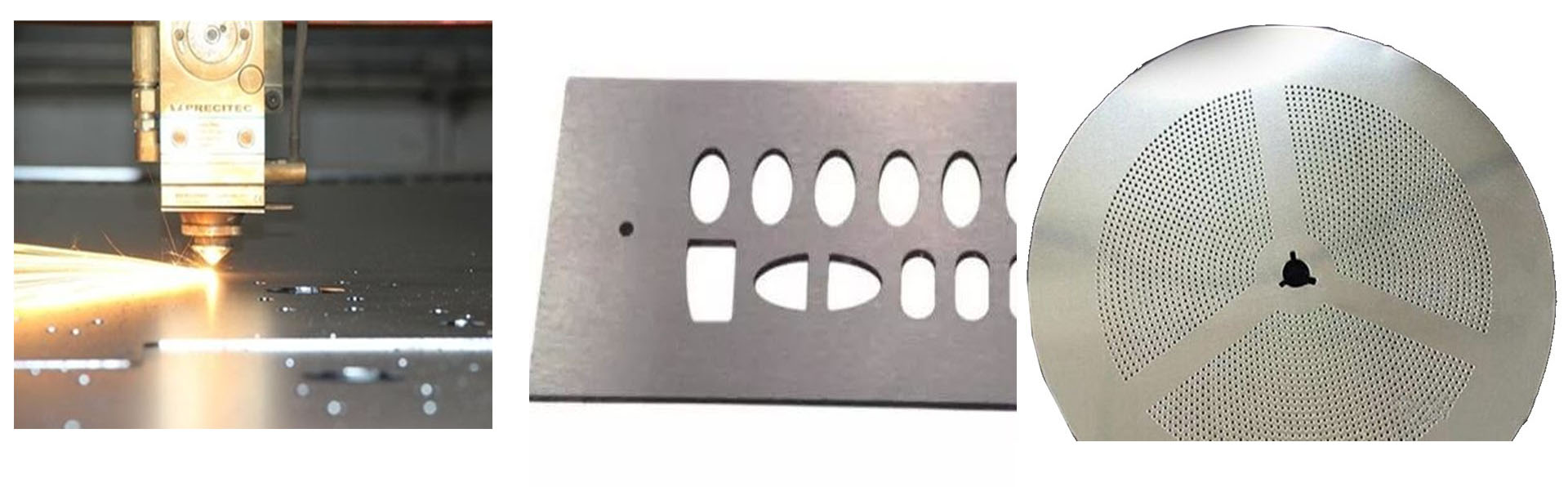

Laser drilling technology has significant advantages compared with conventional hole drilling methods such as mechanical drilling and EDM:

(1) The punching speed is fast, the efficiency is high, and the economic benefit is good. (2) A large aspect ratio can be obtained. (3) It can be carried out on various materials such as hard, brittle, and soft. (4) No tool loss. (5) Suitable for a large number of high-density group hole processing. (6) Small holes can be machined on the inclined surface of materials that are difficult to machine.

II. Classification of laser drilling

1. Copy method:

The laser beam is repeatedly irradiated to a fixed point of the workpiece with a certain shape and precision, and there is no relative displacement of the beam and the workpiece in a direction perpendicular to the direction of propagation of the radiation. The copy method includes single pulse and multiple pulses. Multi-pulse methods are currently used, which are characterized by minimizing the lateral diffusion of energy on the workpiece and helping to control the size and shape of the holes.

A pulse width of the order of milliseconds allows sufficient heat to diffuse along the axial direction of the hole, rather than being absorbed by the surface of the material. The shape of the laser beam can be obtained with an optical system. A shaped hole can be punched out, for example, in a focused beam or in the front of the lens with a hole of the desired shape.

2. Contour roundabout method.

The shape of the machined surface is determined by the trajectory of the laser beam and the relative displacement of the workpiece being machined.

When machining with the contour roundabout method, the laser can operate in both pulsed and continuous states. In the pulse mode, since the holes are successively superposed on each other with a certain amount of displacement, a continuous contour is formed. With contour machining, the hole can be enlarged to have a cross section of any shape.

III. Laser drilling equipment

1. Laser drilling laser:

The laser is an important part of the laser drilling equipment. Its main function is to convert the power provided by the power system into laser energy with a certain conversion efficiency. According to the nature of the working substance of the laser, it can be divided into a gas laser and a solid laser. The gas lasers used for perforation mainly have carbon dioxide lasers, and the solid-state lasers used for perforation mainly include ruby lasers, neodymium glass lasers, and YAG lasers.

Carbon dioxide lasers have many unique advantages. They are more efficient than other lasers and can be absorbed by many non-metallic materials such as plexiglass, plastics, wood, multi-layer composite sheets, quartz glass, etc. More importantly, CO2 lasers can deliver high power output compared to other lasers. When combined with other technologies, high-speed drilling can be achieved with a maximum speed of 100 holes/second, which is difficult for other lasers.

Even so, due to the inconvenience of focusing and dimming of carbon dioxide lasers, the one-time investment of equipment is relatively large, and it is not as popular as other three laser applications in laser drilling equipment.

Solid-state lasers are widely used in laser drilling for their unique advantages. Its main advantages are: (1) short output wavelength. (2) The output light can be transmitted by ordinary optical materials. (3) The whole machine is small in size, easy to use and maintain, and the price is lower than that of the carbon dioxide laser.

2. Laser drilling machine:

The simple and versatile form of laser drilling is a three-dimensional machine tool. The two-dimensional motion is in the horizontal plane, represented by X and Y. The two coordinate axes are perpendicular to each other, and the third-dimensional Z-axis is perpendicular to the Z-Y plane.

Each dimension can be driven by a stepper motor to move the ball screw on a linear ball guide. Its accuracy is determined by the accuracy of the lead screw and the accuracy of the ball guide. If equipped with a microprocessor system, the 3D machine tool can complete laser processing of various holes in the plane and group holes in a certain range.

When it is necessary to machine a series of holes in a pipe or barrel material, the machine tool should have a five-dimensional function. In addition to the three-dimensional mentioned above, the added two-dimensional is a 360-degree rotation of the XY plane. We define it as the A-axis, XY. The plane is tilted from 0-90 degrees in the Z direction, which we define as the B axis.

With so many types of laser drilling, the five-dimensional workbench can do the job. In the case of saving equipment investment, the CNC of the B axis can be changed to manual. This will save money and basically complete all punching tasks.

3. Laser drilling machine:

In recent years, the level of laser drilling machine at home and abroad is at a stage of rapid development. The output power of the laser is gradually increasing, the pulse width is narrower and narrower, the frequency range is wider and wider, and other parameters are becoming more and more favorable. The direction of punching is developing.

The flexibility of the control portion of the light guiding system and the laser drilling machine is continuously increased, so that the punching range is continuously expanded. At present, there are dozens of laser drilling machines that have formed commodities in China. In addition to colleges and universities and research institutes, companies specializing in manufacturing laser equipment are gradually increasing. This shows that China's laser processing is moving towards industrialization.

IV. Laser drilling process

1. Process:

The first step is to learn more about the punching materials and punching requirements.

The second step is to simulate the experiment and test.

The third step is to design a convenient and fast fixture.

The fourth step, programming.

In the fifth step, effective punching and necessary testing are implemented.

2. Main parameters affecting the quality of punching:

The process of laser drilling is an extremely complex thermophysical process in which lasers interact with matter. Therefore, there are many factors that affect the quality of laser drilling. In order to obtain high-quality holes, the parameters affecting the quality of the holes should be analyzed and understood according to the general principles and characteristics of laser drilling. These parameters include: the energy of the laser pulse, the pulse width, the amount of defocus, the repetition frequency of the pulsed laser, and the nature of the material being processed.

3. Auxiliary process:

In order to improve the precision of laser drilling, it is sometimes necessary to adopt some auxiliary process steps and process measures, including:

(1) applying a positive pressure on the surface of the workpiece, or installing a low pressure chamber on the reverse side of the workpiece, which may help The vaporized material is removed during the punching process and the liquid phase is removed.

(2) Install a photodetector in a safe position below the workpiece to detect the penetration of the workpiece in time.(3) Covering the workpiece with a liquid film or metal platinum can reduce the taper of the hole and prevent the liquid phase from splashing.

(4) In order to prevent the melt from accumulating in the hole in time, a substance having a vaporization temperature lower than the melting temperature of the material to be processed may be placed behind the workpiece to be processed.

(5) Using a laser as a processing tool to punch holes in the workpiece, and then using other methods to achieve the required accuracy. At present, there are generally used mechanical processing of silicon carbide, punching, wire for aperture finishing, chemical etching and the like.