CO2 Fly Laser Printer used in the pharmaceutical industry

2019-08-13source:cycjetaccess:3662

Abstract: Fly Laser printers have a wide range of applications in pharmaceutical packaging.

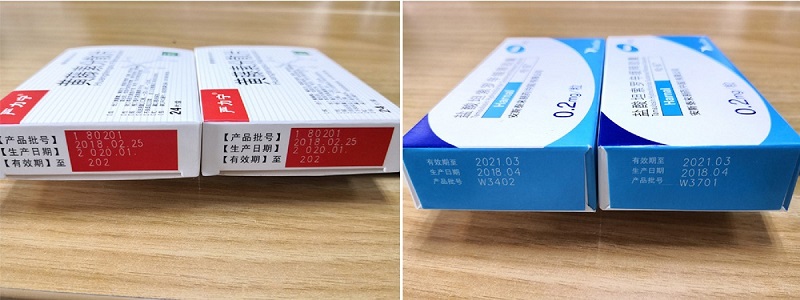

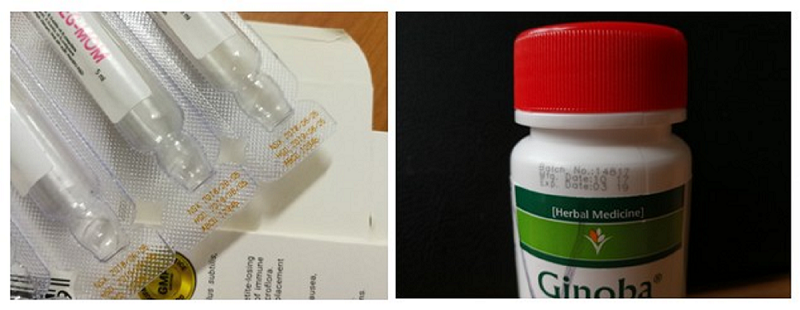

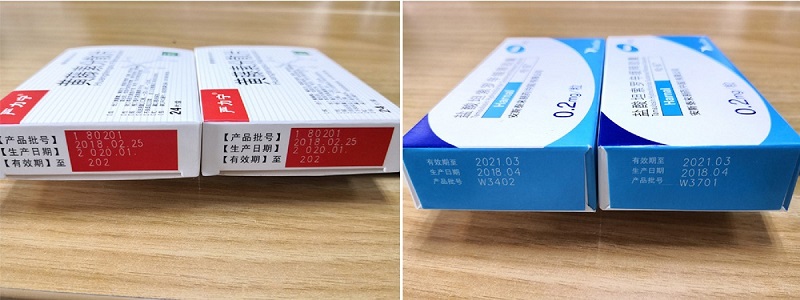

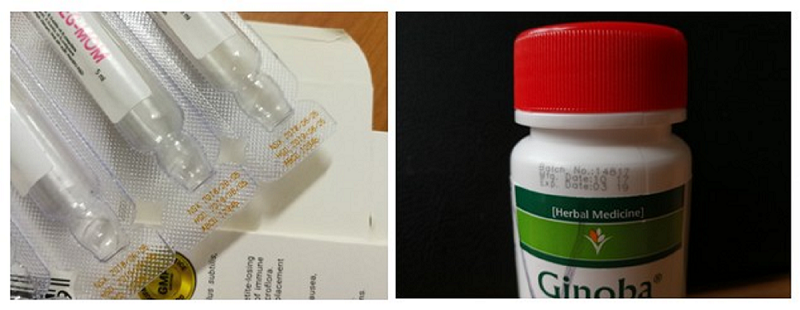

Now, because the pharmaceutical industry is fully implementing GMP certification, it has very strict standards for various medical equipment and medical packaging materials. At the same time, the packaging requirements for pharmaceuticals are high-speed and clean, and there are many different shapes for medical packaging bottles and medical packaging boxes. At this point, the pharmaceutical industry needs to use its laser coding and marking machine to form its own specialized material handling system. In addition, in the downstream stage of the coding process, high-pressure sterilization of the vial is required, which requires good adhesion of the label, and requires relevant environmental certification for the ink and solvent of the printer. The pharmaceutical company supervision code is applied to the surface of paper boxes, coated paper, coated paper, aluminum foil paper, plastic packaging and so on.

The pharmaceutical industry's automatic printing database, date, time, batch number, class, serial number, etc. are far more diverse than some food enterprise identification needs. Faced with the characteristics of various industries, for the pharmaceutical industry, the selection of printers and consumables must be done with a lot of effort. Now laser printers can help. Whether it is from research and development, production to intelligent manufacturing, according to the characteristics of the industry, targeted transformation, laser marking machine can achieve more environmentally friendly marking, more efficient field application, the degree of automation is higher than the same type of products, functionality Configuration should also be stronger.

What solutions does the laser printer have in the general packaging of the medicine box? In terms of kit packaging, CYCJET laser engraving machine provides a series of integrated automation solutions for high-speed production lines and micro-products, including printing production date or serial number directly at the mouth of small plastic pill boxes. In the face of many customer requirements, the laser printer is more outstanding, it is a more environmentally friendly green logo application, the initial procurement cost will be relatively high, but the later use cost will be very low, and the failure rate is low, marking The content has anti-mite, anti-counterfeiting and other functions, which is very suitable for some pharmaceutical companies with strict environmental protection requirements.

In the future, not only need to meet the simple identification problem of pharmaceutical manufacturers, but also the overall solution of automated logo retrospective marketing, providing the “one thing and one yard” logo service for the pharmaceutical industry. Here, Shanghai Yuchang Industrial Co., Ltd. has done I have done a traceability system for a lot of companies. After quality control of the drug from the source, do a good job in front-end production, at the back-end consumer side, do a good job of drug introduction and information collection to help companies make decisions.