Aluminum Can Marking Solution

2019-07-30source:access:3291

1. What is the market outlook for canned beverages?

The advantages of aluminum-can packaging are generally recognized over other beverage packaging types, and consumer preferences for canned beer or soft drinks are also affecting the choice of beverage packaging. In 2015, the global beverage industry, the market share of canned beverages reached 245 billion, accounting for 23% of all packaged beverages. It is estimated that by 2020, this figure will reach 278 billion, an increase of 2.4% compared with 2015.

2. How is the production of canned beverages distributed globally?

The world's largest producers of canned beverages, the United States, Japan, China, Brazil, the United Kingdom, Mexico, Spain and Canada, account for 73% of global production. Among them, especially China's growth is the fastest.

3. Canned drinks, is the marking important?

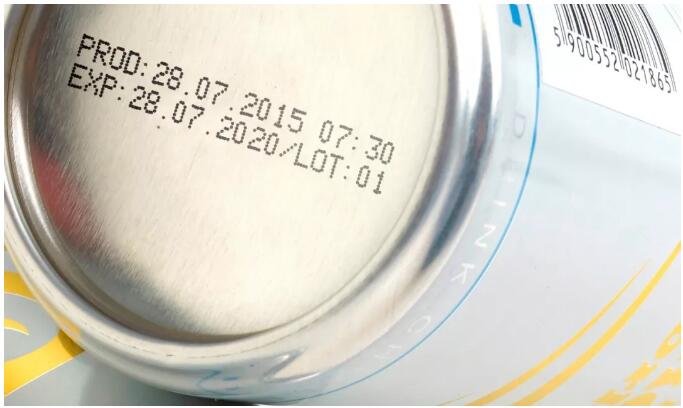

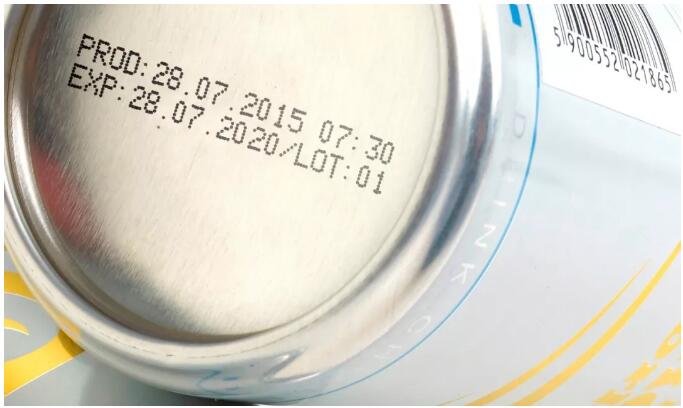

In the production of canned beverages, the important role of the marking is to highlight the traceability and serialization requirements. On the production line, each beverage can is assigned a human eye and a machine-readable traceability code. These codes are constantly being identified and stored throughout the supply chain, not only in the quality of the product, but also as a key tool for identifying, recalling or withdrawing. It is also a tool for consumers to obtain accurate information about their products.

4. What are the difficulties in the marking of canned beverages?

The difficulty of marking canned beverages is reflected in the following aspects: line speed (currently, the typical soft drink canning line speed is 600 cans/minute, the industrial inkjet printer needs to match this speed at the minimum), and the harsh production environment ( Beverage cans are more common in wet and sugary production environments, temperatures up to 45 ° C), and the difficulty of the surface of beverage cans (most canned products, markings are marked on the bottom of the can, the surface is concave, marking the surface The unevenness, combined with the speed of the production line, exacerbates the difficulty of the marking. An indication of extension or blurring is often related to the speed of the production line, but it is also possible that the marking system is not suitable for the surface of the tank.

Therefore, a suitable identification marking system needs to overcome these first.

5. Currently, the most widely used technology for marking is?

Continuous inkjet coding printer (CIJ)is the traditional way of coding aluminum cans. Now, fiber laser marking technology has become another option for canned beverage labeling applications.

6. What are the application advantages of CYCJET CIJ inkjet printer?

CIJ's advantages are mainly due to its ease of installation, ease of use, and its high adaptability to high-speed production lines and uneven surface assignments. The combination of printhead and ink is the key to achieving CIJ's high quality assignment. In other words, only CIJ, which adapts to line speed and combines diversified inks to further optimize performance, ensures high quality marking in the most demanding canning and packaging environments.

7. Fiber laser marking machine as an alternative to CIJ technology, what are the main advantages?

The wide application of laser marking technology in the beverage industry has long been popular. It is flexible enough to be used in most packaging types and can reproduce high-resolution fonts and graphics. The biggest advantage of fiber laser technology is that it can help customers to complete the heavy coding task, and at the same time realize the customer's desire to avoid consumables.

In the application of canned beverages, fiber lasers can be marked with bare aluminum, coating or anode aluminum due to their high pulse peak power, leaving an indelible mark on the surface after anodizing (this process) There is no marking action but actually creates a protective layer on the aluminum surface). Fiber lasers can successfully achieve a balance between high-resolution marking and high-speed marking.

8. Fiber laser printer be suitable for high-speed production of canned beverage production lines?

Absolutely okay. Taking the CYCJET LF30F as an example, the speed of the LF30F is 42,000 cans per hour, with 60 characters per aluminum can. If calculated with a conventional logo length between 10 and 26 characters, the speed can reach 90,000 cans per hour.

9. The country is paying more and more attention to environmental protection. Is there any environmental factor that needs attention in the assignment of canned beverages?

More and more companies are committed to fulfilling their social responsibilities and tend to purchase technologies that improve the quality of their environment. The identification products are both energy-intensive and volatile organic chemicals. When purchasing a suitable CIJ product, you need to first consider whether the chemicals such as ink used have relevant compliance certificates.

What are the advantages of 10 fiber laser machines in the company's environmental certification?

The environmental performance of the LF30F is another feature. Laser technology does not require any consumables to be replenished and does not involve any waste disposal. This is a great benefit for the company's green certification, and will also increase the recycling rate of aluminum can packaging.